Manufacturing process and flow of floor-Standing Evaporative Air Cooler With Remote Control LBW-4000/LBW-4000RC

I. Preliminary preparation

Design and planning:

Determine the design specifications and functional requirements of the product based on market demand and user feedback.

Design the appearance, internal structure and size and shape of the parts of the product.

Plan the production process and determine the required materials and equipment.

Material procurement:

Purchase high-quality key parts such as fans, water pumps, evaporative filters, and shells.

Ensure that the purchased materials meet environmental protection and safety standards.

II. Parts manufacturing and processing

Fan manufacturing:

Process fan blades and motors to ensure their dimensional accuracy and performance.

Perform dynamic balancing tests on fans to ensure that they do not generate excessive vibration and noise during operation.

Water pump manufacturing:

Process the impeller, pump body and motor of the water pump.

Test the flow and pressure of the water pump to ensure that it meets the design requirements.

Evaporative filter manufacturing:

Use special materials to manufacture evaporative filters, such as honeycomb filters.

Waterproof and anti-corrosion treatment is applied to the evaporation filter to increase its service life.

Shell manufacturing:

Manufacture the shell of the product according to the design requirements.

Spray or paint the shell to improve its aesthetics and corrosion resistance.

III. Assembly and debugging

Component assembly:

Assemble the fan, water pump, evaporation filter, shell and other components.

Connect the circuit and water circuit to ensure that the connection between the components is firm and reliable.

Complete machine debugging:

Performance test of the assembled whole machine, including cooling effect, noise level, energy efficiency ratio and other indicators.

According to the test results, adjust and optimize the whole machine to ensure that its performance meets the design requirements.

Quality control:

In the manufacturing process, quality inspection is carried out on each process.

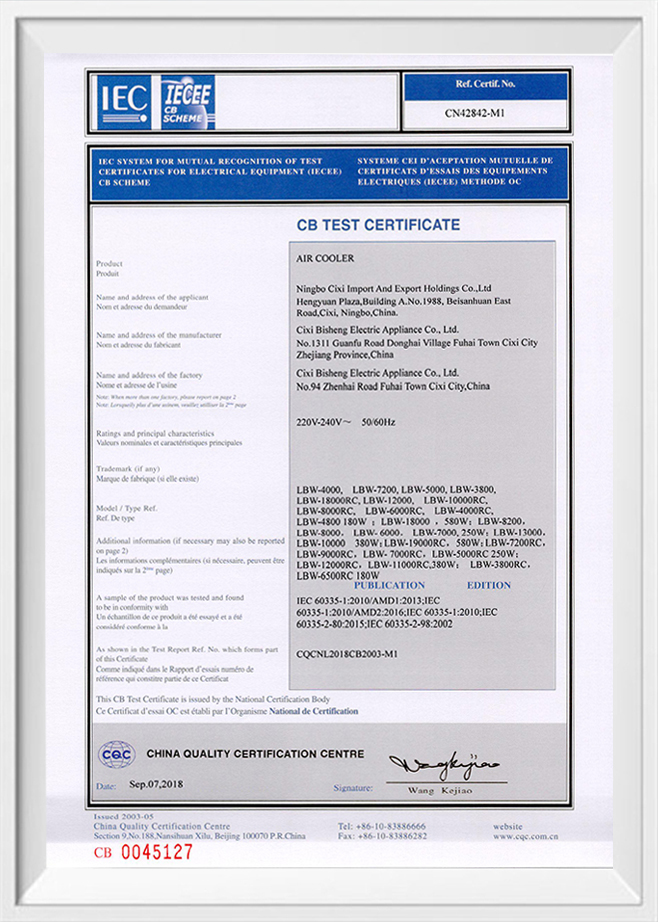

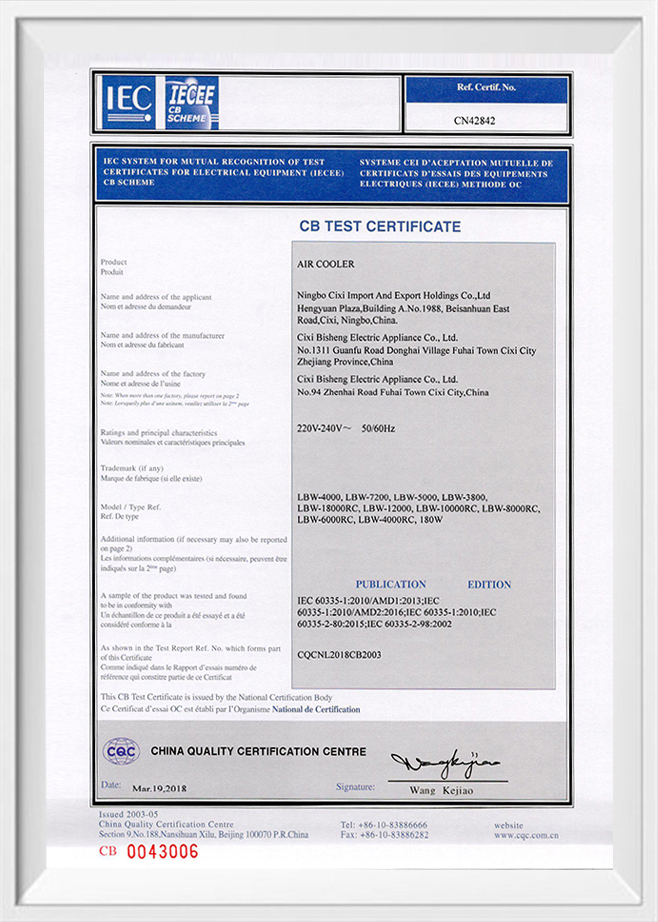

Sampling inspection is carried out on the finished product to ensure that its quality meets the relevant standards and requirements.

IV. Packaging and transportation

Product packaging:

Use appropriate packaging materials and methods to package the product.

Indicate the model, specifications, production date and other information of the product on the packaging.

Transportation and delivery:

Transport the packaged products to the designated location.

During transportation, take care to protect the product from damage.

V. After-sales service and support

Product maintenance:

Provide product maintenance services to ensure that product failures during use can be resolved in a timely manner.

Technical support:

Provide technical support and consulting services to users and answer questions encountered during use.

English

English 中文简体

中文简体 Español

Español