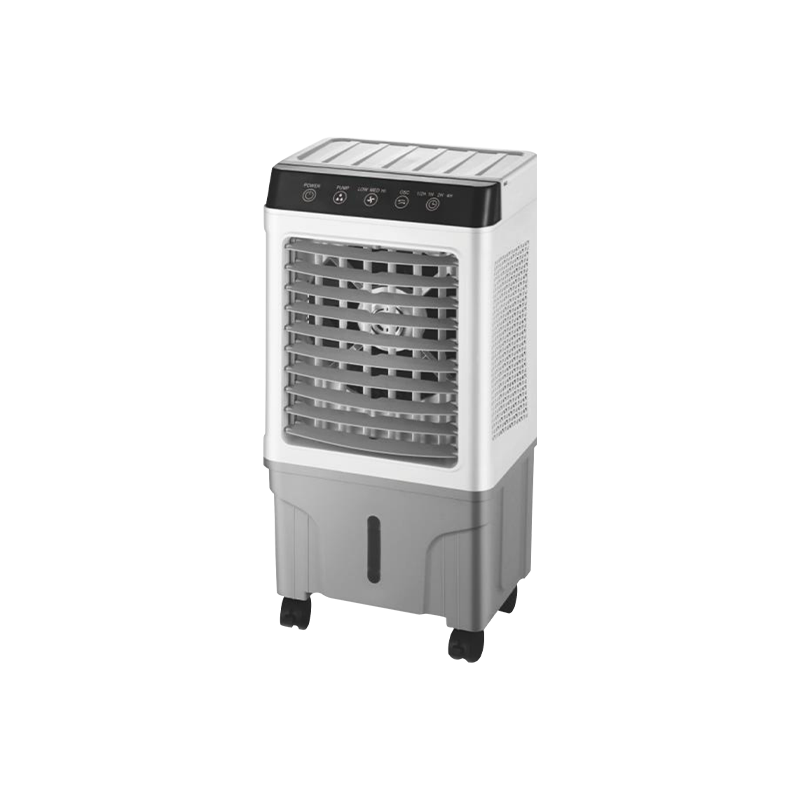

The impact of the external dimensions of the Low Energy Consumption And Low Noise Industrial Air Cooler LBW-16000RC on installation and movement

1. Space requirements

Installation location: The size of the equipment directly determines the installation space required for it. The ideal installation location should have enough space to facilitate the normal operation, maintenance and repair of the equipment. If the equipment is too large, it may limit the layout of other equipment, resulting in reduced space utilization.

Adaptability: In an environment with limited space (such as a small factory or office), larger equipment may not be placed, and the size of the available space must be taken into account. It is necessary to measure in advance and ensure that the equipment can adapt to the intended location.

2. Difficulty of handling

Weight and volume: The net weight (28kg) and size of the equipment make it difficult to carry. Appropriate tools such as trolleys, forklifts, etc. are required when moving to avoid damage or personal injury due to improper handling.

Transportation channel: During the transportation of the equipment, ensure that the channel width is sufficient so that the equipment can pass through narrow areas such as doorways and corridors smoothly. In addition, the space limitations of stairs and elevators must be considered during transportation to ensure that the equipment can be safely transported to its location.

3. Installation method

Fixed or mobile installation: Larger equipment is usually more suitable for fixed installation because it is more complicated to move. Small equipment can be flexibly set up in different locations to meet different usage requirements.

Installation foundation: For equipment with heavier weight, a special foundation or base may be required to ensure its stability and safety. This may also involve the load-bearing capacity of the ground.

4. Heat dissipation and ventilation

Space heat dissipation: The design of the equipment should take heat dissipation into consideration and ensure that there is enough space around for air circulation to avoid overheating of the equipment. Small installation space may lead to poor heat dissipation, which will affect the working efficiency and service life of the equipment.

Ventilation requirements: If the equipment is placed too compactly, it may limit its heat dissipation, resulting in a decrease in cooling effect. Therefore, a certain amount of ventilation space should be maintained around the equipment.

5. Aesthetics and layout

Overall layout: The size of the equipment may affect the layout of the entire work area. Larger equipment may become the visual focus and affect the overall aesthetics. The coordination of the equipment with other furniture and equipment needs to be considered when designing the workspace.

Visual impact: The appearance and size of the equipment may affect the working environment and comfort of employees. Large equipment may appear visually oppressive, so the layout design needs to be considered comprehensively.

6. User Operation

Operational convenience: The height of the equipment (1305mm) may affect the user's ease of operation, especially for workers of different heights. Consider how to make the operation more user-friendly when designing, ensuring that all users can easily access the control panel and maintenance parts.

Maintenance space: The size of the equipment also requires sufficient space around it for daily maintenance and cleaning. Ensure that all parts are easily accessible to reduce maintenance time and costs.

English

English 中文简体

中文简体 Español

Español